Innovative Microplastic Removal Technology Wasser 3.0 PE-X®

Removing microplastics from (waste)water

Wasser 3.0 remove is the ecological and economical alternative to installation-, maintenance-, energy- and resource-intensive (filtration) processes.

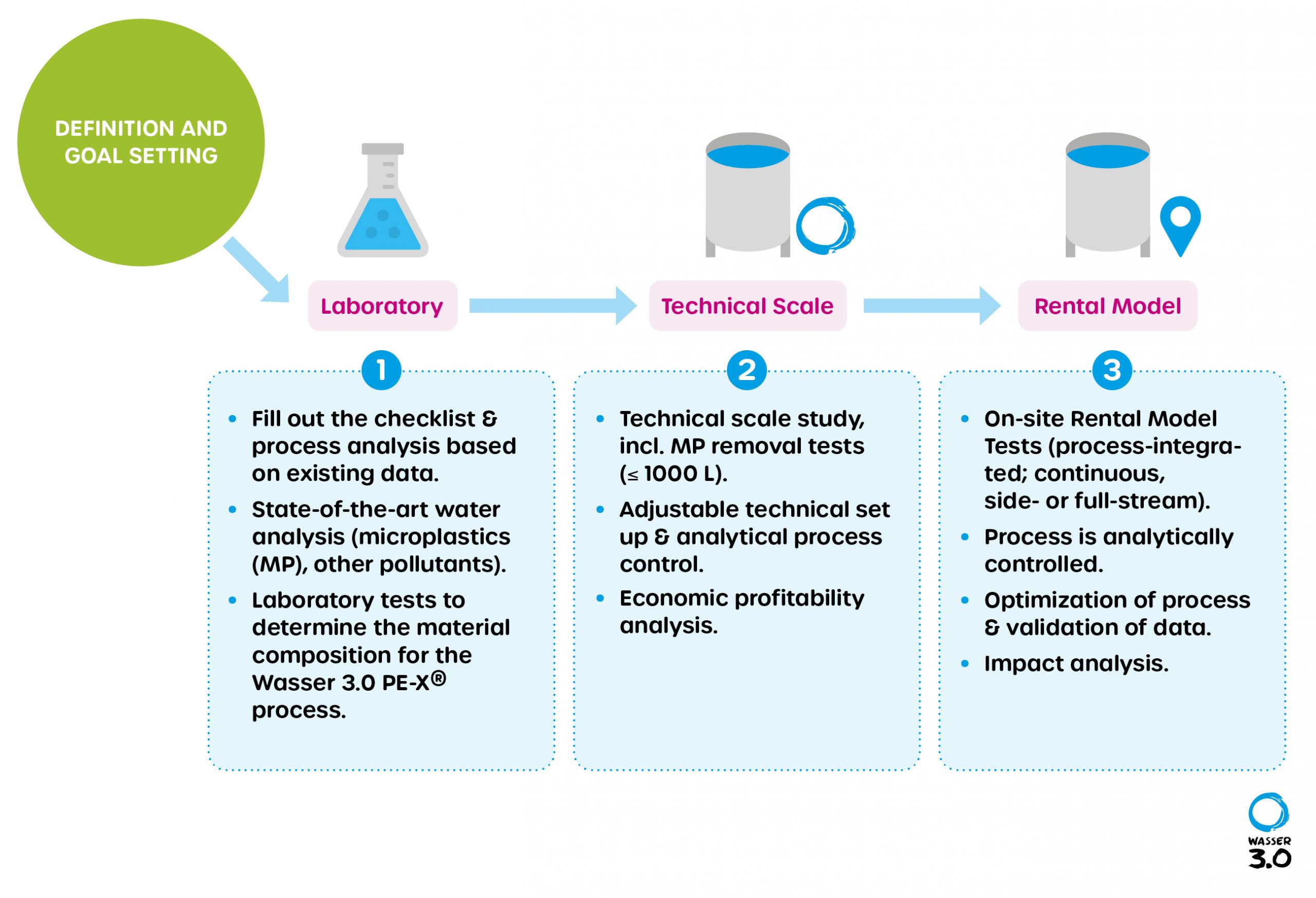

With Wasser 3.0 PE-X® we have developed a modular, adaptive, and scalable material-technology composition to meet the increasing complexity of pollution scenarios with efficient solutions.

Our low-tech plants and filter-free processes perform significantly better than the competition in all parameters. They can be implemented cost-effectively, not only in central wastewater treatment plants (WWTPs), but also along the plastics value chain as a precautionary measure to prevent the transfer of plastics from processes into the environment and reduce microplastic concentrations. In addition to primary and secondary microplastics, we are targeting a previously unaddressed field. We offer solutions for microplastic-free production.

Modularer Aufbau des Mietmodells zur Entfernung von Mikroplastik aus (Ab-)Wässern | © Wasser 3.0

Microplastic removal using Clump & Skim Technology

With Wasser 3.0 PE-X® we have developed the first filter-free process solution for the fast, efficient, and cost-effective removal of microplastics and other pollutant classes from different types of water.

Based on the principle of agglomeration-fixation (in short: clump & skim) and by precisely matching materials and technology to the process in question, all microplastic particles are clumped together to form particle aggregates - regardless of polymer or water type.

Coarse-pored separation units are used to remove the formed agglomerates. This saves both costs and immense maintenance effort, which increases continuously with decreasing particle size.

Upon customer request, tailor-made solutions are developed, adapted to the composition of the wastewater and the (legal) requirements for discharge into the wastewater system.

The goal is to reduce the overall pollutant load in the wastewater, especially microplastics, micropollutants and COD, and to improve the overall sustainability of the processes without incurring high energy requirements, costs, and maintenance efforts.