Microplastics reuse & circular economy

Closing loops: New ways to reuse microplastics.

Waste, which includes microplastic agglomerates from our removal processes, are valuable materials. How these valuable remnants get back into value chains is part of our work in reuse.

Wasser 3.0 reuse ends linear action; treated waters and removed agglomerates are reused.

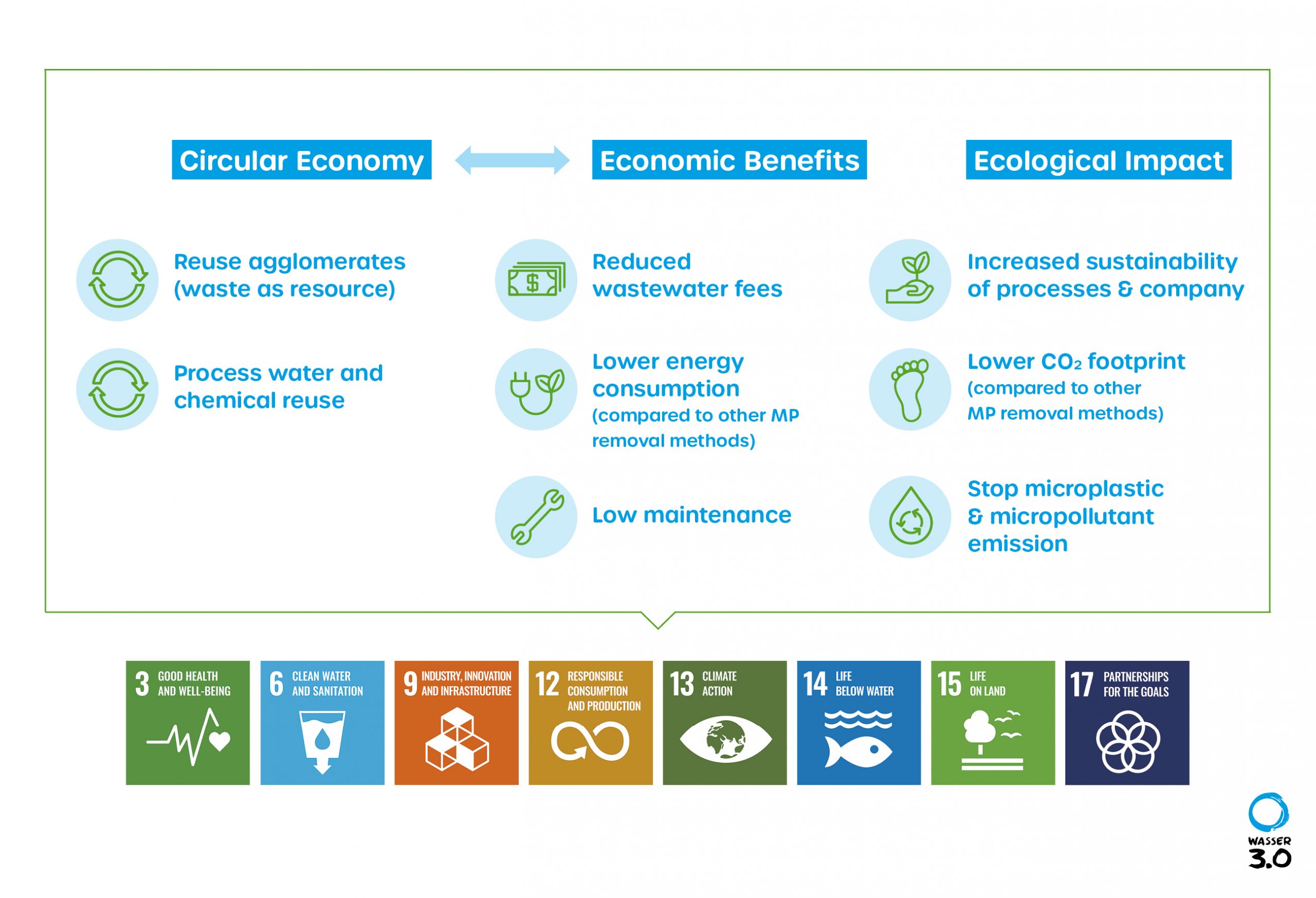

The key: circular economy solutions go hand in hand with resource conservation and environmental protection.

From the beginning of our feasibility studies and in the field of innovation transfer, we think about the end. This includes identifying reuse concepts for our microplastic removal products.

The waste products from Wasser 3.0 PE-X® become the basis for new products. Thermal incineration is the last option for us, if at all.

#detectremovereuse: Circular economy strategy for (waste-)water treatment.

Through our reuse processes (embedded in the fully sustainable process design), we reduce the need for fossil resources, reduce the carbon footprint, and combine the requirements of Zero Waste and Circular Economy.

We work with you to develop modular and adaptive solutions for water without microplastics and micropollutants. At the same time, we deliver savings in energy, CO2, water, waste, and operating and maintenance costs. Through the multidimensional approach of microplastic-free production, you will not only achieve measurable contributions to the achievement of the UN sustainability goals, but you will also address tomorrow's requirements and regulations – today.

We see wastewater treatment as a value-added process.

The treated waters can either be reused as process water or discharged as wastewater free of microplastics or micropollutants. For each application of our removal technology there is an individual as well as tailor-made reuse concept, depending on the pollutant composition and water properties.

We act based on current and future legislation and legal requirements, solution-focused and with measurable impact.