Forever Chemicals – PFAS (Part 2)

19. January 2024

WASoMI training platform launched

8. March 2024

Forever Chemicals – PFAS (Part 2)

19. January 2024

WASoMI training platform launched

8. March 2024Microplastics in industrial wastewater

With increasing legal regulations for polymers, plastics and microplastics, high costs for water, waste, energy, chemicals, and plant maintenance, as well as complex pollution scenarios - companies that use a lot of water, polymers and other chemicals in their processes are facing the challenge of realigning their environmental, waste and resource management.

The Wasser 3.0 PE-X® process provides, for the first time, an adaptive complete solution for a cost-efficient sustainability upgrade for industrial water treatment. The process focuses on the removal of microplastics and is based on green chemistry, low-tech systems, and circular economy processes. With low acquisition and operating costs, it not only improves the resulting water quality, but also reduces resource utilization, waste generation and less energy demand compared to the competitors.

Detecting microplastics: municipal wastewater treatment plants vs. industrial wastewater

Wastewater from plastic manufacturing or processing industries is often highly polluted with microplastics (MPs) and high levels of oxidizable organic matter, which results in a high chemical oxygen demand (COD).

When the high microplastic load enters wastewater streams, it is a large burden for municipal wastewater treatment plants (WWTPs).

WWTPs are not designed to remove microplastics, and due to the high volumes of wastewater released, they are important point sources of microplastics into the environment and water cycle.

Further, the majority of the microplastics end up in sewage sludge, whereby the problem is only displaced. It is therefore essential to avoid the input of MPs into wastewater streams by targeting their removal from upstream point sources such as industrial wastewaters. Targeting an upstream removal (start-of-the pipe) is more effective, involves lower costs, and ensures that the polluter bears the costs instead of the public.

Microplastic removal from wastewater: New feasibility study published

As early as 2021, we were able to carry out a long-term trial on the simultaneous removal of microplastics and micropollutants at the municipal wastewater treatment plant in Landau. In 2023, we had the opportunity to test our rental model in an in-house pilot operation at a plastics processor for the removal of microplastics and simultaneous reduction of COD from industrial wastewater. In a total of eight test phases over a period of three months, our research and development work focused on reproducibility, impact analysis, and economic feasibility.

In each test phase, 12 samples were analyzed for six parameters: COD, total suspended solids (TSS), particle count, pH, turbidity, and filterable solids (AFS). Microplastic removal is accomplished through the physical-chemical agglomeration fixation of microplastics from the water. We use innovative hybrid silica gels that can form a few large agglomerates from many small particles in a non-toxic way without harmful by-products. The COD reduction was carried out using a fixed-bed reactor filled with modified absorbent materials. We have now published the results.

Briefly summarized: In addition to microplastic removal and COD reduction, this treatment also enables the reuse of wastewater and agglomerates, which leads to a reduction in the CO2 footprint and represents a measurable and significant upgrade in terms of ecological impact.

Link to the EU project UPSTREAM

Since mid-2023, we have been an active research and development partner of the EU-fundedUPSTREAM project.

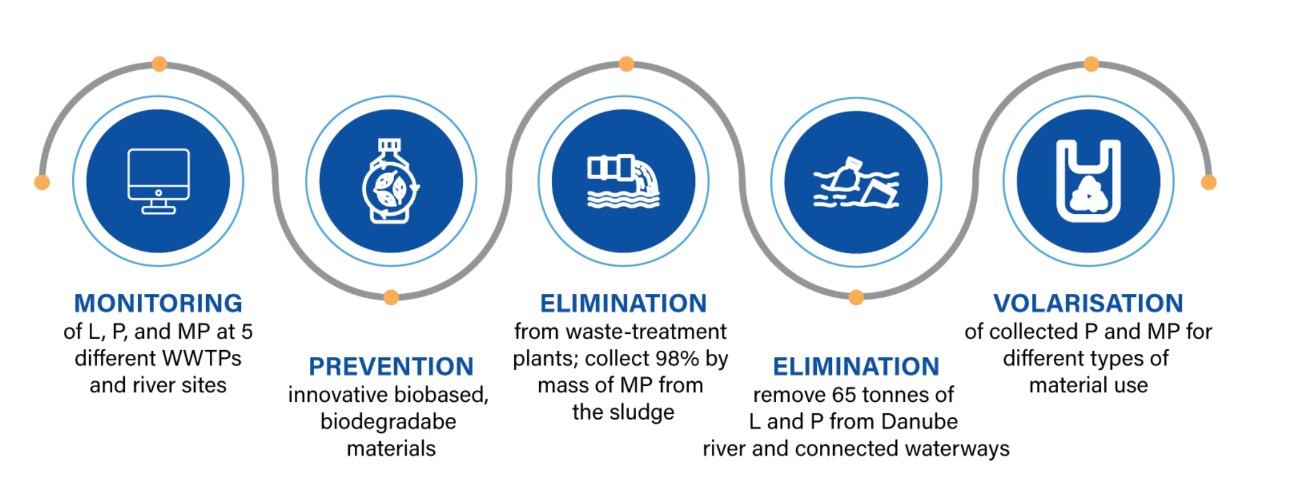

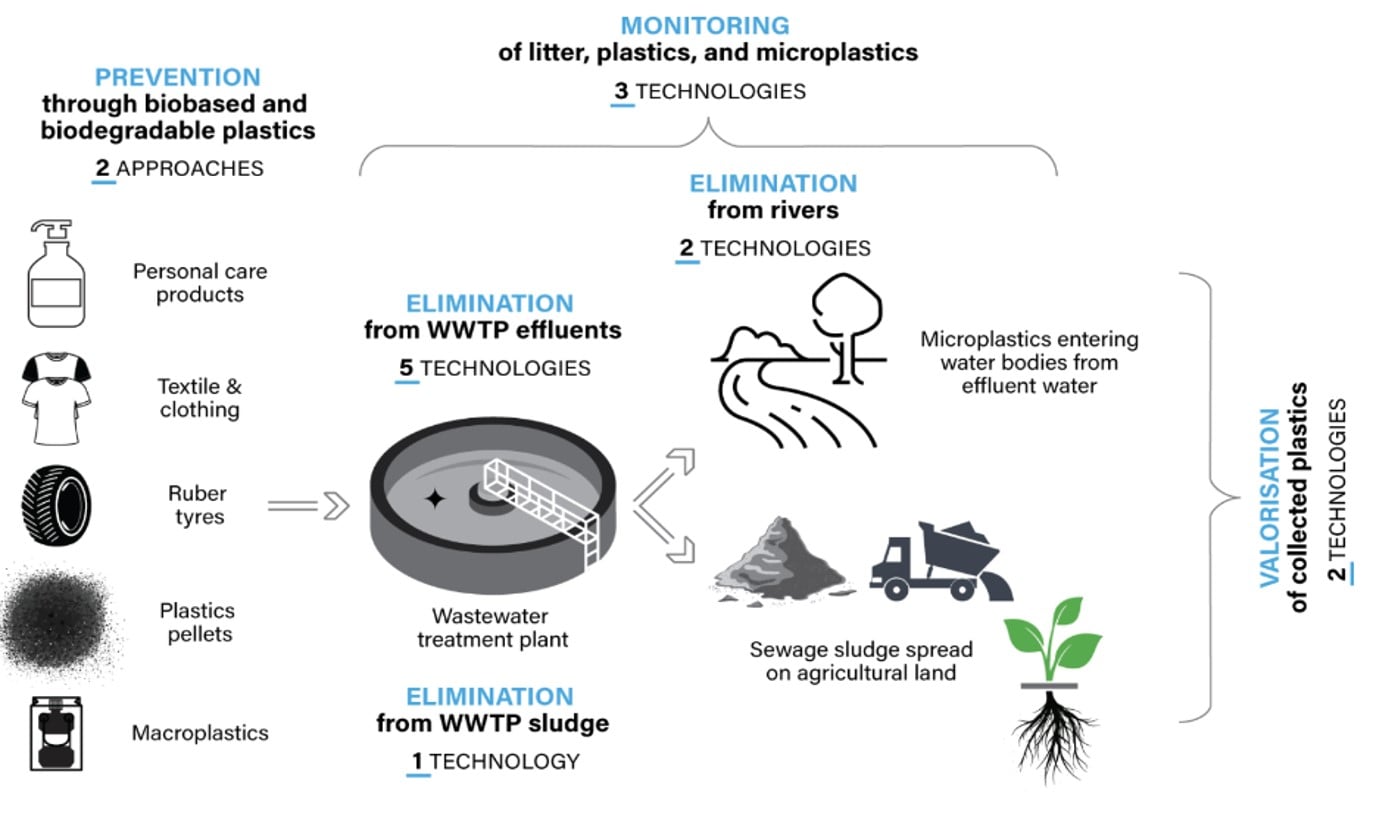

We support the project consortium in addressing the challenges related to the monitoring, prevention, elimination, and valorization of waste/litter (L), plastics (P) and microplastics (MP).

We are one of four WWTP-integrated demo sites addressing pollution at each stage of the water system, connected to seven rivers in five countries. The UPSTREAM consortium will establish circular value chains that have the potential to reduce plastic waste by 50% and microplastic pollution by 30%. Progress in UPSTREAM is based on some of the best innovations in the world, including:

- Standardized, rapid monitoring techniques that can detect microplastics down to > 25 μm in size.

- Bio-based, biodegradable plastics that prevent the formation of MP in consumer products and wastewater treatment plants themselves.

- Innovative floating platforms capable of removing more than 83% of L, P and MP directly from rivers, both on the surface and in the riverbed.

UPSTREAM represents a pan-European consortium with five demonstration plants across Europe, including four wastewater treatment plants (UK, ES, DE, IT) and a test site on the Danube in Serbia. The kick-off was last year. We will soon be coming together in Barcelona to tackle the next milestones.

Photo from the first UPSTREAM project meeting in the UK (©Upstream Consortium)