Partner in Mission: Van Remmen UV Technology

30. May 2023

Forever Chemicals – PFAS (Part 1)

5. July 2023Artificial turf pitches - a source of microplastics in the environment?

What are the advantages of artificial turf over natural grass?

Natural grass is clearly superior to artificial turf from an ecological point of view. It can support the natural functions of the soil which helps to break down pollutants. Through water absorption and evaporation, it also has a cooling effect in summer. Artificial turf cannot compete here; it offers no ecological function, seals surfaces, and strongly heats up in the summer. Natural turf also offers better playing characteristics and has lower purchase costs.

So why is artificial turf preferred to natural grass? This is because natural grass can only withstand a limited period before it can no longer regenerate itself from the damage caused by use – around 800 hours per year. If a longer service life is needed, artificial turf is essential. Further, artificial turf can be used without any problems during heavy rain, unlike natural grass, and requires less maintenance.

Currently, around 9000 artificial turf pitches are in operation in Germany, mainly for soccer, but sports such as hockey, tennis, football, or rugby, as well as school sports, also use artificial turf pitches. In some cases, the usage time can exceed 2500 hours per year and artificial turf pitch. For an average use of 1800 hours per year, three natural grass pitches would be necessary.

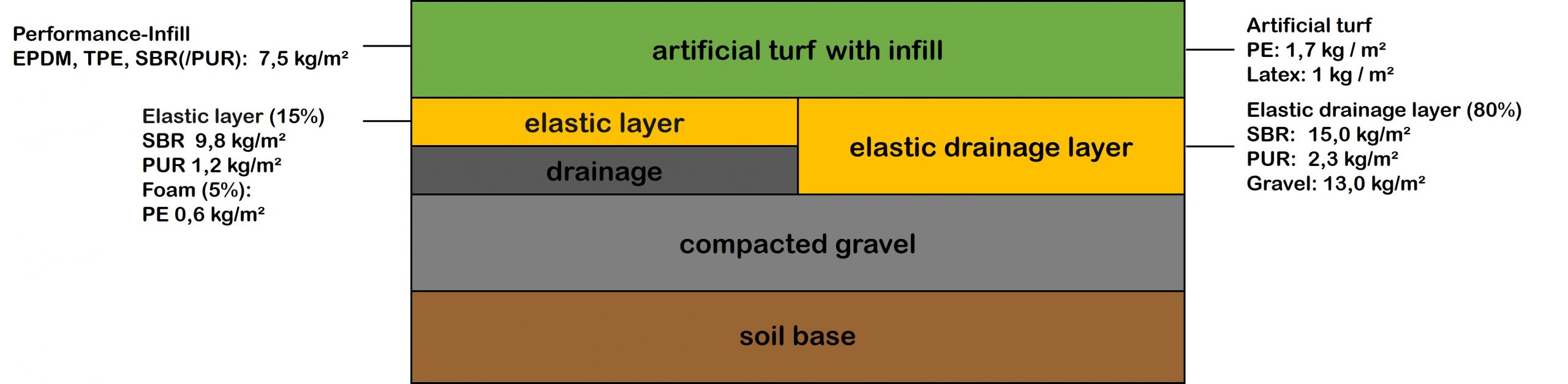

Structure of the artificial turf

Artificial turf pitches consist of various layers and an infill. An unbound base layer including a drainage system (to drain off rain and backwater) is applied to the subsoil to level the ground and provide cushioning. On top of this, an elastic bearing layer is applied, usually consisting of used tire granulate with a polyurethane-based binder. An alternative to this is an asphalt layer with an applied elastic layer, also consisting of used tyre granulate and binder. This layer simulates the spring comfort of natural grass.

The actual artificial turf is applied to this cushioning substructure. This consists of polyethylene or polypropylene turf, which simulates the blades of grass and is bonded in a fabric consisting of polyethene or polypropylene or polyamide. They are rolled out and applied in long strips on the elastic layer.

To fix the turf, e.g., against wind, it is weighed down with sand as an infill or bedding. Usually 20 kg/m³ of infill or bedding are added to the turf. Additional performance infill can be added to improve the playing characteristics. Plastic granulates based on SBR (styrene-butadiene rubber, shredded used tyres), EPDM (ethylene-propylene-diene-monomer rubber) or TPE (thermoplastic elastomers) lead to particularly good playing properties. Cork can also be used as an ecological alternative. The elastic layer or elastic base layer has a service layer of approximately 30-40 years before it needs to be renewed. The artificial turf carpet itself can be used for 12-15 years. After this, it must be disposed of or, ideally, recycled, which is another challenge of artificial turf.

Microplastic emissions and transport

When looking at artificial turf pitches, it is noticeable that the infill granulate and artificial turf fibres can be found throughout the environment surrounding the pitch. On average, 2.2 tonnes of plastic-based performance infill must be refilled per artificial turf pitch every year. Where does it disappear to? What happens to the artificial turf fibres that come off the artificial turf carpet?

Part of the need to replenish the performance infill comes from the compaction during use, which causes it to lose its function. Significant portions of the infill are discharged into the environment through various pathways. Especially in humid conditions, the infill granules can stick to shoes and clothing and are thus discharged into the environment. When removing leaves and snow and performing other maintenance work on the artificial turf, additional infill is discharged, since it cannot be separated from snow or leaves.

Wind and precipitation result in further transport of the infill. Granules can be transported at wind speeds as low as 18 km/h, with significant losses and transports over long distances during strong winds and storms. Heavy rain also leads to high losses through surface runoff, as it is washed off the pitch.

Through use, the plastic fibres from the artificial turf carpet dissolve over time. Estimates range from 0.2 to 1.3 t of fibre loss per year and artificial turf pitch, making them the second largest source of microplastics. second source of microplastic.

Some of the microplastics released end up in the landfill through cleaning operations and thus not in the environment. The rest ends up in the drainage systems or the surrounding soils via wind and surface runoff. Depending on the presence of separate or combined sewers, the microplastics from the drainage systems end up in the sewage treatment plant or directly in the environment. Studies show that the microplastic accumulates in the surrounding areas, leading to a significant increase in pollution of the surrounding soils. Another part of the discharged microplastic can be transported over long distances by wind and water and thus spread throughout the environment.

Reliable data on the discharge quantities of the various pathways are not yet available; estimates vary greatly depending on the study. The values determined through field tests or mass balances range from a total of 300 kg/artificial turf pitch and year to 5000 kg artificial turf pitch and year. Thus, artificial turf pitches are the second largest source of direct microplastic input into the environment after tire abrasion.

To assess the environmental risks and take effective measures against microplastic emissions, it is essential to investigate and understand the discharge pathways. The aim is to clarify how much microplastic is released into the environment from artificial turf pitches and to move from pure estimates to real, reliable data collection. At Wasser 3.0, we are trying to close the gaps with our cost-effective method for detecting microplastics (Wasser 3.0 detect), which can also be used for microplastics from artificial turf pitches. An important factor here is to determine the right and efficient sampling location, as well as in which areas and at what time the samples have to be taken.

A way out without microplastics? Making artificial turf pitches more sustainable

Attempts to retain microplastics on artificial turf pitches are proving difficult to implement. Filtration devices can retain microplastics from drainage water, but not those microplastics discharged by wind, surface runoff, or those that are adhered to clothing. Appropriate methods to clean clothes after use are another option. In addition, barriers (walls or palisades) can partially capture plastic blown by the wind. Adapted strategies for the removal of leaves and snow can also reduce microplastic discharge. This can reduce but not prevent the release of microplastics. Therefore, the focus should be on alternative, sustainable materials in artificial turf construction.

The simplest way to increase the sustainability of artificial turf pitches is to avoid the use of plastic-based performance infill. This can be replaced by more environmentally friendly cork infill. It is also possible to use only sand as infill, but this reduces the playing characteristics of the artificial turf and does not prevent the release of microplastics through the loss of fibres in the artificial turf itself. Here, manufacturers are encouraged to make it more robust against abrasion or to use natural, environmentally friendly materials.

There are currently no laws or regulations to limit microplastic emissions from artificial turf pitches. In the EU, there are discussions about banning plastic-based performance infill. The European Chemicals Agency ECHA recommends a ban on plastic-based infill with a 6-year transition period. The ECHA considers SBR granulate from shredded car tyres, which contains a high level of various pollutants, to be particularly problematic. But EPDM and TPE can also contain numerous pollutants. The artificial turf fibres themselves are not included in the discussion.

Here, Wasser 3.0 would like to develop a clear basis for decision-making by collecting data to effectively reduce microplastic inputs via artificial turf fields. Thanks to the cost-effective detection methods based on novel fluorescence markers, it is possible to detect microplastics in an cost-effective and reliable way and thus obtain transparent and comparable data. This enables further decisions and the development of effective prevention strategies; only if the amount of microplastics emitted and their pathways are known, can preventative strategies be effectively evaluated and implemented.

Conclusion - artificial turf modern sports facilities with a clear environmental impact

Due to their long service life and lower maintenance requirements, artificial turf pitches are increasingly preferred to natural grass sports facilities. Numerous studies show that artificial turf fields release high amounts of microplastics into the environment via the loss of plastic-based infill and the microplastic fibres of the "turf", thus resulting in a high environmental impact. The microplastics are transported by wind and water and end up in the surrounding soil or waterways. Since the advantages of artificial turf pitches are offset by such a significant disadvantage, we are faced with the question of whether it makes sense.

Various construction measures are being discussed to reduce microplastic discharge. However, the use of environmentally friendly and sustainable materials for artificial turf construction seems to be the better way forward. Currently, the ban of plastic-based performance infill is being discussed at the European level, but political efforts are limited. However, due to the high quantities of microplastics that continue to enter the environment year after year via artificial turf pitches, this should be done with greater urgency. Once in the environment, microplastics cannot be removed and will remain there for decades to centuries due to their longevity.