ChangeNOW Summit 2023

1. May 2023

Oleg Zernikel came to stay

13. May 2023Two questions - one blog: How microplastics are created during washing? Are the available solutions real solutions?

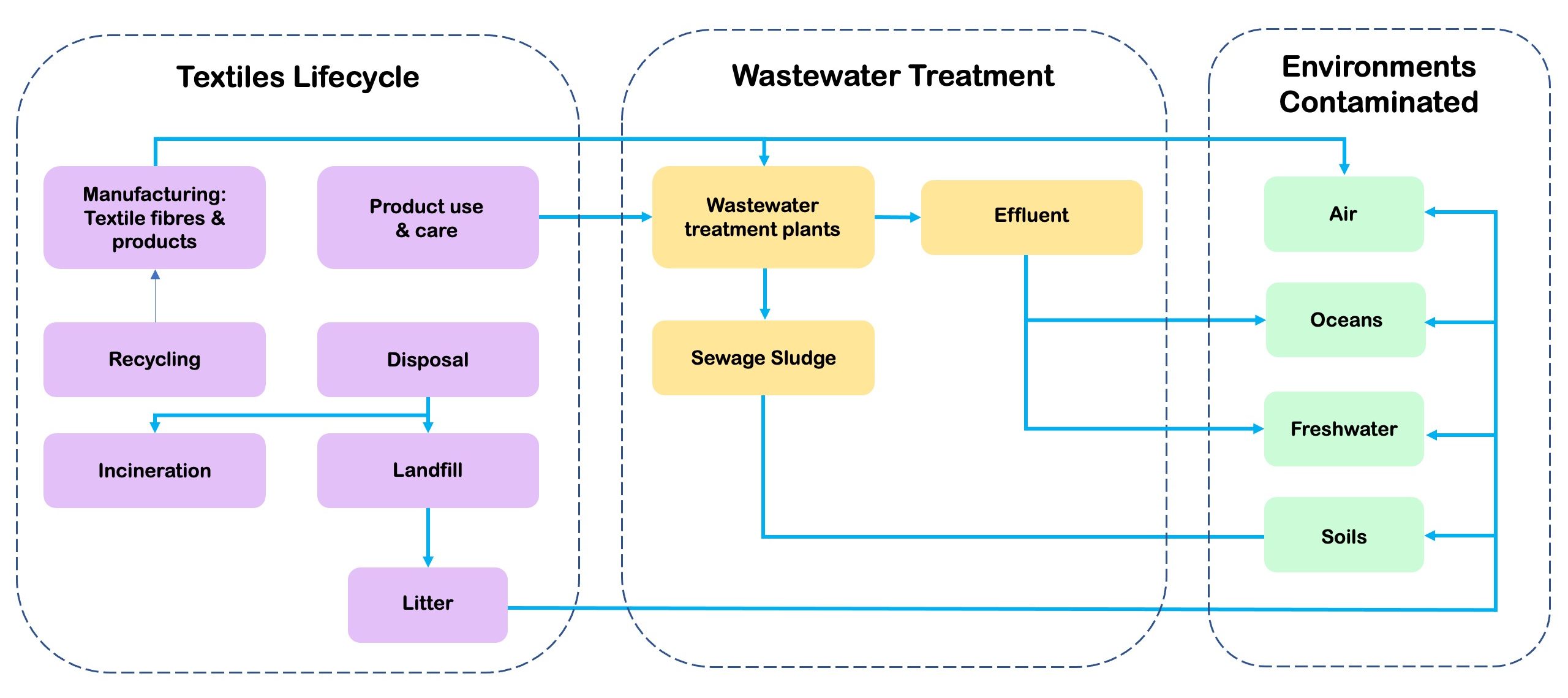

Textiles made of synthetic materials such as polyester (PES), polyamide (PA), or elastane (EL) are one of the primary sources of microplastics and microfibres in the environment.

Today, 60-70% of clothing is made from synthetic fibres and the washing of these clothes is estimated to account for approximately 35% of the microplastics that enter the marine environment worldwide each year amounting to between 200,000 and 500,000 tonnes.

Various strategies to minimise this source of input are currently being discussed. Textile manufacturers are being encouraged to sustainably optimise their products for durability and longevity, the use of harmless chemicals, and the production of innovative materials from recycled and natural fibres.

In recent years, washing machine manufacturers, various start-ups and two "Jugend forscht" winners have also developed ideas and methods for reducing the amount of microplastics in the environment caused by washing synthetic clothes.

In this article, we take a closer look at the various prevention strategies, including their effectiveness and user-friendliness.

How are microplastics created in the washing process?

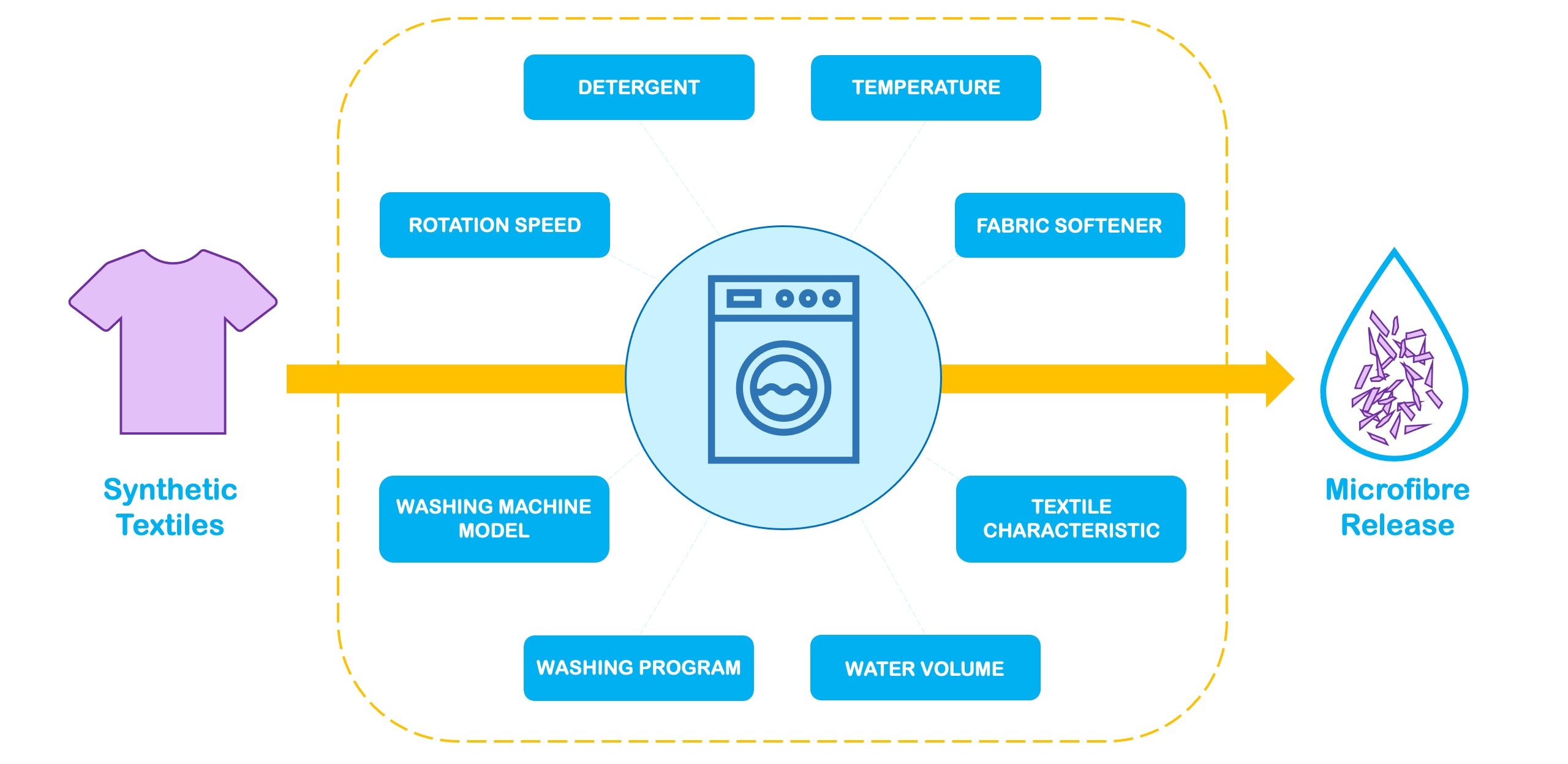

During each wash cycle, textiles are subject to mechanical (rotation, friction) and chemical (water, detergent, fabric softener) stress. This is necessary to remove dirt from the laundry. However, hundreds of thousands of micro- and macro-fibres and particles are also released, which end up in the wastewater and ultimately the environment. It is estimated that a single garment can release between 120 and 700,000 particles during one wash cycle.

Hence, the amount of fibres and particles produced per wash cycle depends on many different factors, some of which interact with each other. This makes it difficult to determine the exact influence and efficiency of these factors. Textile properties such as fibres, yarn properties, textile structure (open or closed), and chemical treatment of the textiles play a significant role in fibre and particle release.

For some washing parameters, studies have already been able to make more conclusive statements about their influence on microfibre release, while for others, study results are inconsistent or contradict each other. However, in general, it can be stated that higher washing temperatures (60-90°C) and high rotational speeds (1200-1400 rpm) increase the mechanical stress and thus the degree of fibre abrasion. The influence of detergent and fabric softener, on the other hand, is not clear and studies come to partly contradictory results. It is discussed that the fibres are protected by the foam formed and thus the fibre abrasion decreases compared to washing without detergent. Some studies, on the other hand, found an increase in the number of fibres when detergents were used.

These differences are partly due to the different study designs, but also to the complexity caused by the number of different detergents and fabric softeners on the market and their (irregular) effect depending on textile properties, washing programme, and washing parameters.

Which regulations exist and which tools are available to minimise the discharge of synthetic microfibres and microparticles through wastewater into the environment?

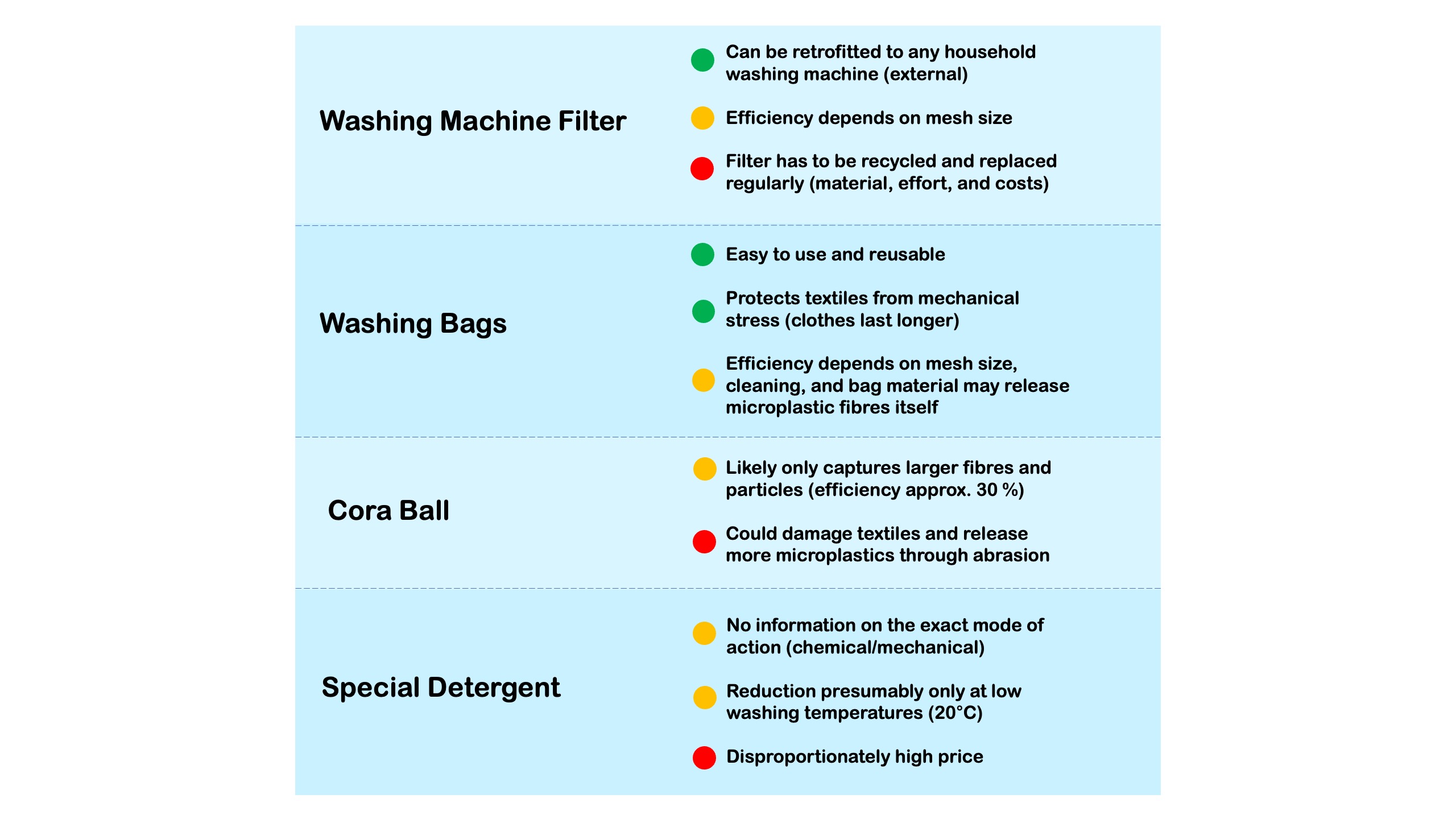

France is the first country to implement regulations: from 2025, newly purchased washing machines must be equipped with a microfibre filter. The filters available on the market so far differ in terms of handling and cost to the consumer. Depending on the mesh size of the filter, not all microplastics are retained.

Washing machine filters can also be retrofitted externally to any standard household washing machine. This involves connecting the filter system to the washing machine's wastewater hose. Some filters must be cleaned by the user, with the contents disposed of in the residual waste, while other filters are sent back to the manufacturer for recycling. This may require consumers to either continuously purchase new filters or ship the filter back to be exchanged for a clean one.

There is also the option of integrating a filter directly in the detergent compartment of the washing machine. Here, too, there are models that can be cleaned yourself or sent to the manufacturer for recycling. Manufacturers usually claim a reduction of microplastics in wastewater of around 90 % (80-99 %) for their washing machine filters.

However, many questions remain on what influence such add-ons have on the life of the washing machine, how effective the filters are (many washing machines have only a few washing programs that run the water through the filter in the detergent compartment), whether the environmental costs of producing and shipping filters outweigh the benefits, and if the captured microplastics are disposed of properly.

There are also discrepancies in the statements on the filter effects.

Independent scientific studies reveal large ranges for the efficiency of the filters. This demonstrates the complexity regarding the relevant parameters as well as the different detection and measurement methods of the studies.

What other products are available, aside from filters?

In addition to filtering the wastewater to reduce the release of microfibres, there are products that are intended to reduce the mechanical and/or chemical stress on the textiles and are added directly to the laundry drum.

A PET laundry bag can reduce fibre breakage during washing and retains worn fibres that can be disposed of in household waste. According to the manufacturer, this is also said to reduce microfibre release by 80 to 100%.

Cora Ball consists of several plastic rings into which the microfibres are supposed to enter and remain during washing. The fibers tend to tangle together and can be picked out for cleaning. The manufacturer claims an average efficiency of 31%. Presumably, mainly larger (micro) fibres are collected, while very small fibres and microparticles continue to enter the environment in the wastewater. In addition, the ball could damage sensitive textiles and thus also increase textile abrasion.

A liquid detergent was also recently launched on the market, which according to the developers is supposed to reduce microfibre abrasion by up to 80%. Independent studies on the efficiency are not yet available. The manufacturer does not provide any information about the exact mode of action, only that the detergent is particularly suitable for washing at low temperatures (20 °C).

There are already several commercially available methods for the filtration of microfibres and microparticles as well as for the reduction of mechanical and chemical stress and the associated fibre abrasion of textiles during washing. However, these are typically associated with very high additional costs and effort for the consumer (i.e. for maintenance or replacement). Further, filters may not capture all types and sizes of microplastics, and due to the lack of uniform test methods, it is not clear how effective and efficient the methods are.

Understanding the full impact of washing machine filters and products requires a comprehensive life cycle assessment, that considers their production, resource use, efficiency, maintenance, shipment, end-of-life (e.g. incineration of plastic-based filters), and disposal of captured microplastics. And while washing machine filters may reduce the amount of microplastics entering the wastewater system, and particularly entering the sludge, they the are not a comprehensive solution to tackling the larger issues of microfibre release and pollution from synthetic textiles.

What about microfibres released during textile manufacturing?

While the consumer phase (wearing and washing) of synthetic microfibre emissions has been primarily in the focus of research – few studies have investigated the amount of synthetic microfibres released during textile manufacturing.

However, it is estimated that the amount of fibres released during this phase, predominantly during drying, printing, and finishing, is estimated to be the same order of magnitude as those from the consumer phase. During these processes, textiles are subject to chemical treatment, washing, and drying. These processes are abrasive and result in high rates of shedding of loosely attached fibres, which are then directly released to waters and the environment if the water is untreated.

But the extent of water treatment varies according to the supplier. While some suppliers have in-plant effluent treatment or a common treatment plant (that often includes two to three treatment stages). Both methods can remove between 85 to 99% of microfibres, however, a study on common treatment plants in China found that these plants still released up to 430 billion microfibres per day. Thus, it is also necessary to target microfibre removal from such the wastewater of manufacturers.

What is needed for real sustainable action?

To determine the most effective approach to tackling microfibre release, much more uniform and reliable data is required on the levels of microfibres released at different stages of the value chain – from textile manufacturing through to consumer use and disposal, including a greater understanding of which factors affect their release and transport.

A holistic approach is required that addresses the design and manufacturing of the textiles, along with the use and disposal. In March 2022, as part of the circular economy action plan, the European Commission presented the EU Strategy for Sustainable and Circular Textiles, that sets out concrete actions to make textiles more “durable, repairable, reusable, and recyclable and to tackle fast fashion, textile waste, and the destruction of unsold textiles”. This includes 3 main pathways to prevent microfibre release from textiles: 1. Design and production, 2. Use and caretaking, and 3. Disposal and end-of-life processes.

Education and behavioural changes are an important component, including a shift away from fast-fashion, adapting washing habits, and considering end-of-life management. Further knowledge is also required on the amount of microfibres released from textiles, which depends on the development of a standardized sampling method, innovative production processes and wastewater treatment to prevent and remove microplastics across the lifecycle.

How is Wasser 3.0 getting involved?

To this end, we have launched our washing machine project, in which we want to systematically investigate the underlying effects and break down interactions between the individual parameters. We use our sample detection method to determine the amount of microplastics.

Through a donation, you can support our multifaceted everyday research on questions around microplastic sources, detection, and prevention.