Partner in Mission: Sondermaschinen Oschersleben

21. April 2023

ChangeNOW Summit 2023

1. May 2023New insights into microplastic removal from WWTPs using advanced treatment methods and our novel Wasser 3.0 PE-X® process.

Wastewater treatment plants (WWTPs) are important point sources of microplastics and micropollutants into the environment.

Most advanced treatment steps are designed to remove dissolved organic micropollutants, they are not intended for microplastic removal. But their capabilities for simultaneous removal of micropollutants and microplastics is often discussed.

At the WWTP in Landau, we tested two advanced treatment steps and our novel Wasser 3.0 PE-X® process, for the removal of microplastics in addition to micropollutants, in a fourth cleaning step plus. The results were recently published open-access in MDPI Water.

This blog provides an overview of our study and the key findings.

Three cleaning steps are not enough

Standard tertiary WWTPs do not efficiently remove the majority of micropollutants, and although they may remove up to 94% of microplastics from incoming wastewaters, they are still a significant source of microplastics due to the high volumes of wastewater effluent discharged.

The revised EU Urban Wastewater Treatment Directive (2022/0345 (COD) (EU UWWTD) requires that many WWTPs be upgraded to target micropollutant removal; however, microplastic removal will not yet be obligatory. In addition to more reliable long-term data on microplastic levels in wastewater effluents, data on potential removal processes and their efficiencies is required to help drive legislation.

Using our standardized detection method, we were able to determine that an average of 572 million microplastics are released in the wastewater effluent of the WWTP in Landau, Germany – every day. Thus, acting now to target their removal at WWTPs and drive changes in industry practices, is required to prevent their ongoing entry and accumulation in the environment.

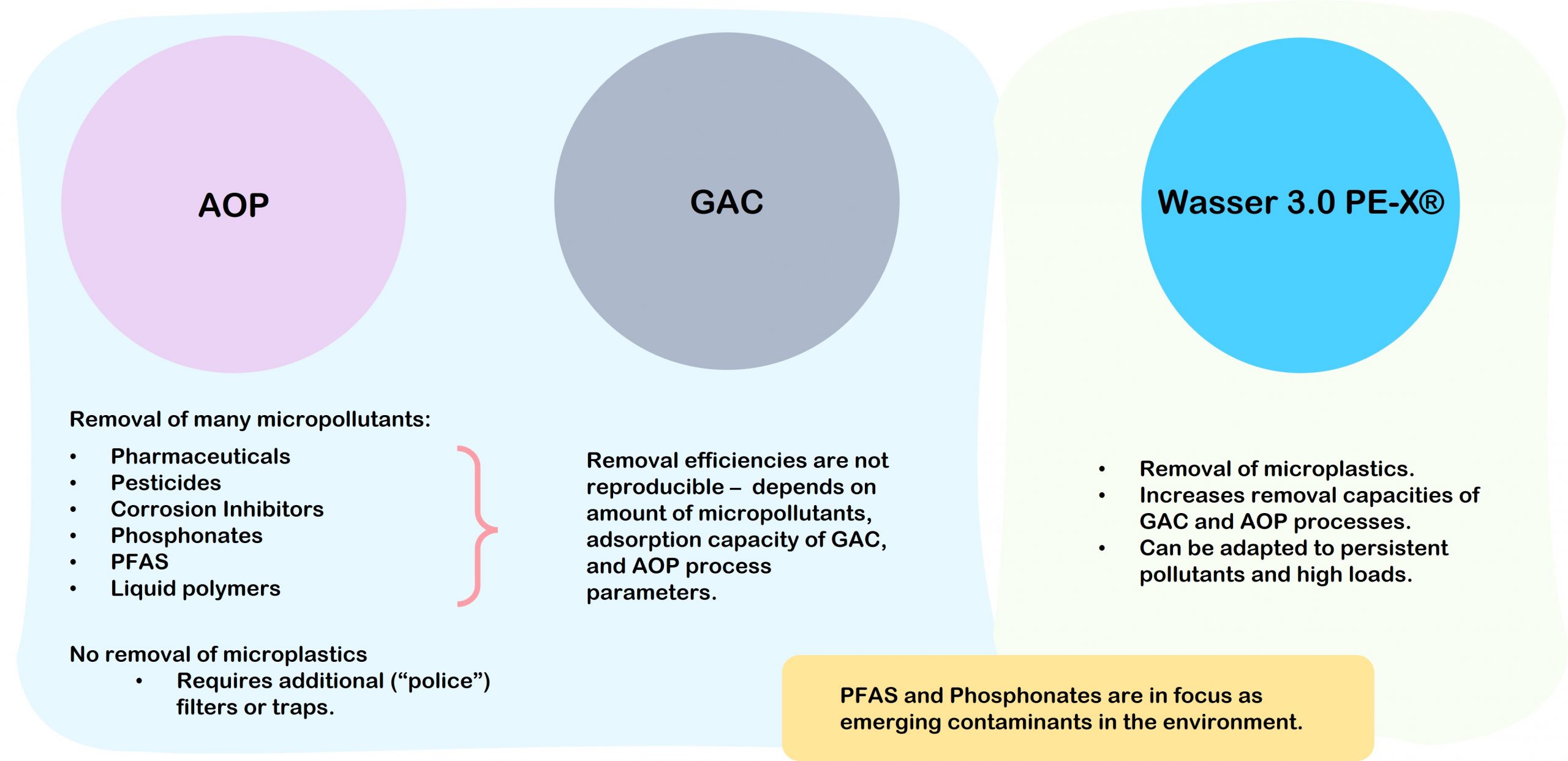

Existing advanced (fourth) treatment steps such as advanced oxidation processes (AOPs) and granular activated carbon (GAC) have been shown to effectively remove dissolved organic micropollutants. But these processes do not target microplastic removal, and their ability to remove microplastics is not yet well studied.

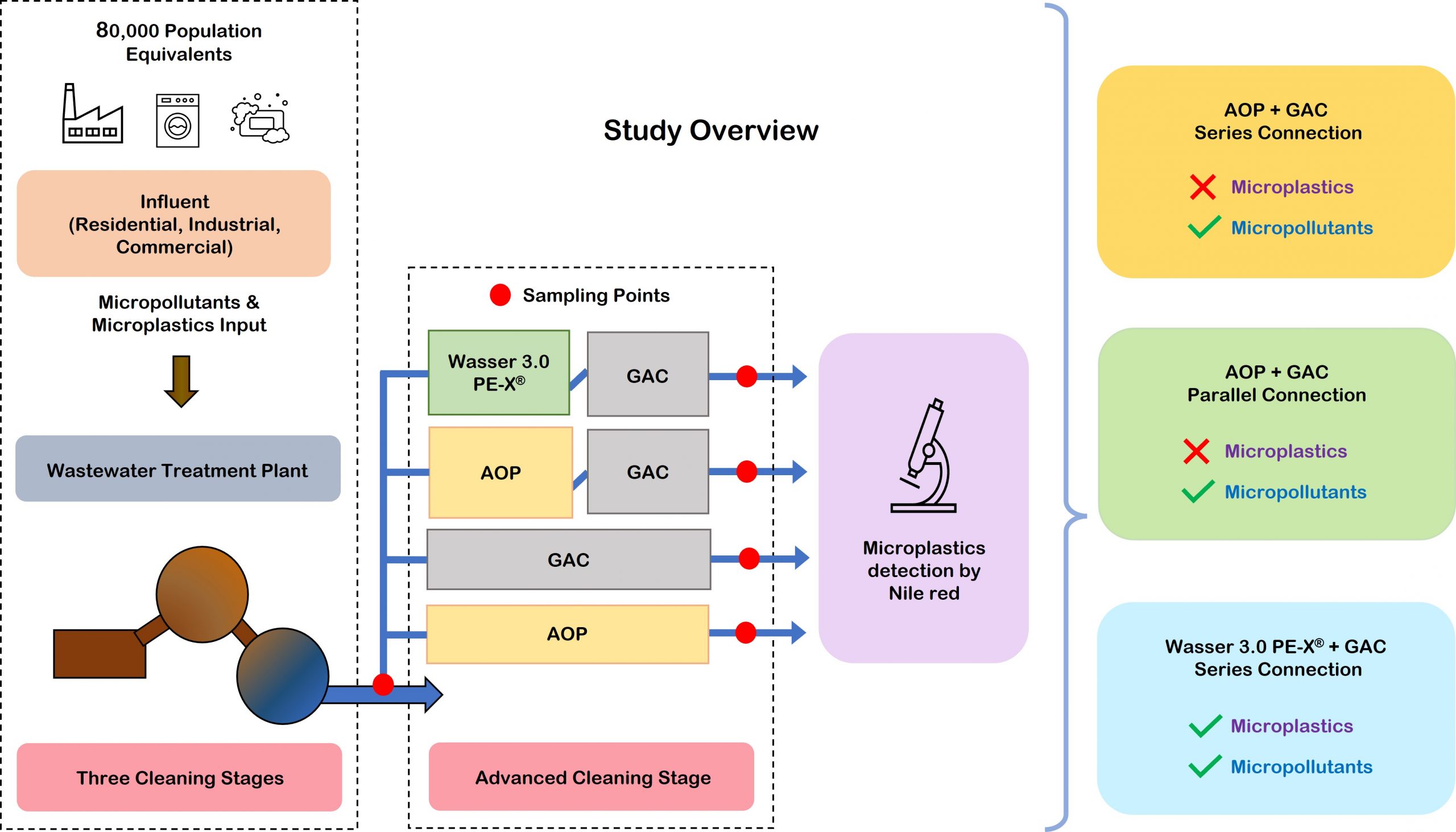

We therefore investigated the ability of an AOP and GAC to remove microplastics in addition to micropollutants. We further tested the simultaneous removal of microplastics and micropollutants with a Wasser 3.0 PE-X® pilot plant connected in series to the GAC. The detection and quantification of microplastics was done using our Nile red-based detection method that enables routine and verifiable monitoring of microplastic levels.

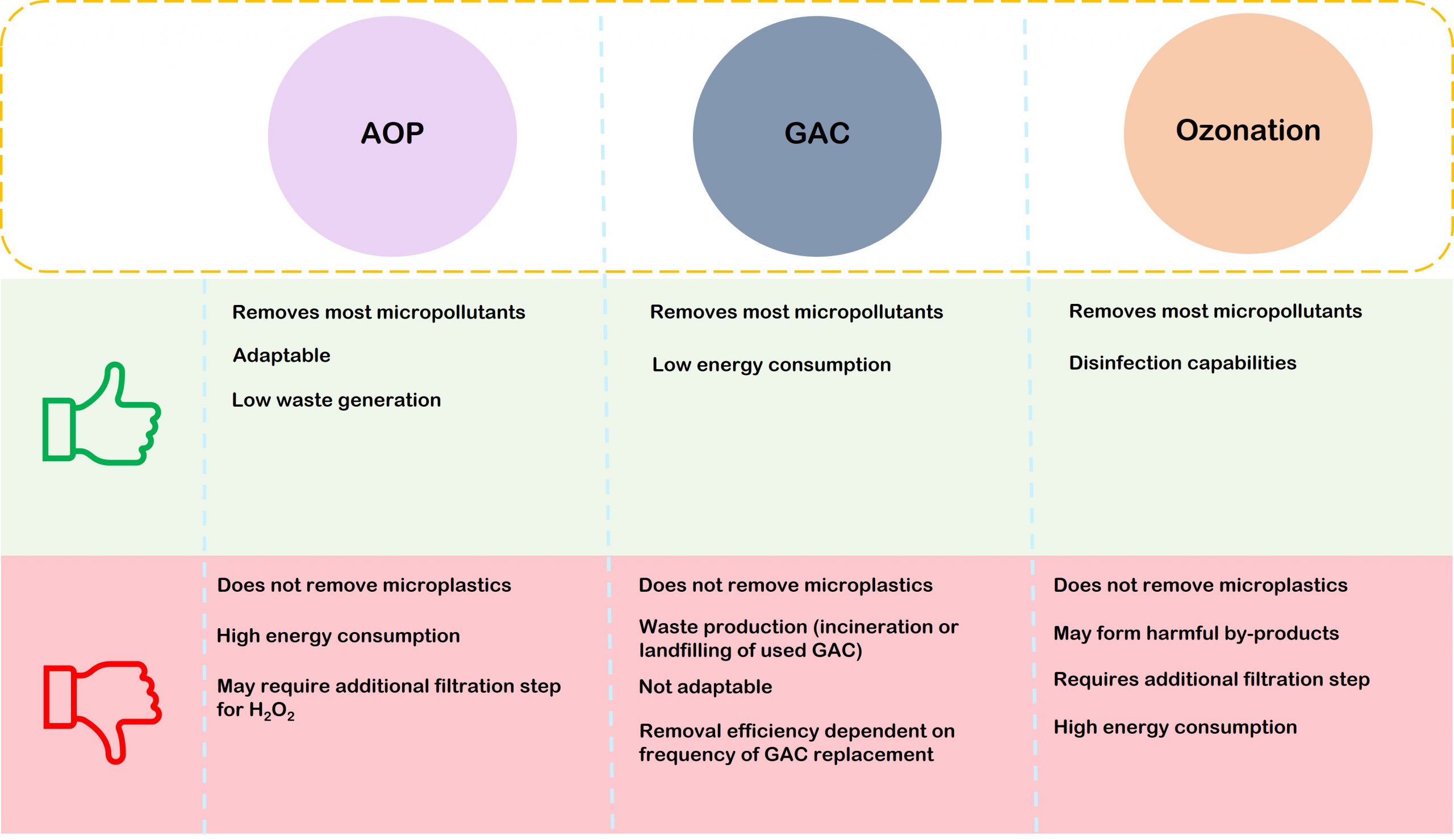

What is the current state of the art for micropollutant removal?

Many micropollutants have been identified as either hazardous or potentially hazardous and may have numerous detrimental impacts on environmental and human health. The revised EU UWWTD has identified 13 micropollutants in two categories that can pollute waters even at low concentrations. And since many micropollutants can pass through the 3 treatment steps of the WWTP, a fourth treatment step will be required for their removal, requiring an upgrade of many WWTP facilities.

The most applied fourth treatment steps include powdered or granular activated carbon (PAC or GAC), ozonation, or advanced oxidation processes (AOP). While PAC and GAC remove micropollutants through adsorption, ozonation and AOP degrade the substances through oxidation. These technologies have been shown to effectively remove (≤80%) dissolved organic micropollutants, but their ability to remove microplastics is not well studied.

But preventative action is key – we need to act now and consider microplastic removal when upgrading WWTPs with an advanced treatment step, rather than waiting until legislation is finally in place – during which time an unprecedented amount of microplastics will have continued to accumulate in the environment.

So, what are effective ways to remove microplastics in addition to micropollutants?

Various methods, such as rapid sand filtration, membrane filtration, and disc filters, have been discussed for microplastic removal from (waste)water. But microplastic characteristics, such as their shape and size, impact the potential removal rates and associated operational parameters. And the smaller the microplastics, the higher the technical complexity of the filtration process. This results in increased costs, maintenance requirements, and energy consumption.

Therefore, new, innovative, and sustainable approaches for effective microplastic removal are required. One promising method is to use a hybrid silica gel, such as Wasser 3.0 PE-X®. Our technology has been tested and validated at laboratory scale for various polymer types in waste- and seawater. Through agglomeration fixation (clump & skim) and through the precise combination of materials and technology for the respective process, all microplastic particles are clumped into particle composites. As they float to the surface of the water, they can be separated using a skimmer without a filter. This saves costs and maintenance efforts, which increase continuously with decreasing particle size.

Which key findings did our studies reveal?

The ability of Wasser 3.0 PE-X® to remove microplastics from wastewater at a pilot plant scale was tested at the Landau WWTP in combination with the GAC, creating a fourth treatment step plus – targeting both micropollutants and microplastics.

The micropollutant removal efficiencies of the AOP and GAC systems were determined in a previous study conducted at the Landau WWTP. It was found that both processes were able to effectively remove micropollutants, with average removals of ~76 ± 6% for AOP (removal efficiency up to 97% achieved, depending on operational parameters) and ~90±5% for GAC.

Measuring the microplastic removal efficiencies for the AOP and GAC units connected in series and in parallel showed that the combination of AOP + GAC had no significant effect on the microplastics removal. This confirmed the need for an adaptation of the fourth cleaning steps to target microplastic removal in addition to micropollutants.

The targeted microplastic removal Wasser 3.0 PE-X® process, when connected in series with the influent of the GAC, resulted in an average micropollutant reduction of 86 ± 2% and microplastic reduction of 61 ± 28%. This is an effective micropollutant reduction, significant microplastic reduction, and demonstrates the potential of the Wasser 3.0 PE-X® process as an effective add-on for microplastic removal in advanced wastewater treatment.

We will further optimize the pilot plant’s water flow conditions and contact time to achieve a more stable and higher microplastic removal performances.

Compared to alternative methods that are often researched and discussed for microplastic removal at WWTPs, such as filtration or flotation techniques, the primary advantages of Wasser 3.0 PE-X® are:

- the low energy consumption

- low technical and maintenance effort

- low investment costs

- no waste production (the obtained agglomerates are intended for reuse)

- its modularity, scalability, and high adaptability – the process can be easily installed as an add-on to existing treatment methods.

So where do we go from here?

We will be implementing a Wasser 3.0 PE-X® pilot plant at the WWTP in Mykonos as part of the EU REMEDIES project where we will test and optimize the process over the next four years. We will also be using our standardized detection method and will obtain long-term data on microplastic levels and removal efficiencies that we will be able to compare to the studies at the Landau WWTP. This will take us one step closer to obtaining comparable data on microplastic levels and removal potentials.

We need to begin removing microplastics from the source now, before concentrations in the environment continue to accumulate. Once in the environment, they are impossible to remove. Such studies help drive policy development and the implementation of impactful microplastic limits. To ensure that we can continue our work on developing effective microplastic removal technologies and continue to monitor our processes and validate our detection results, sponsors and donations are welcome. If you would like to support us, you can find do so here or contact us directly.