Microplastics-invisible threat to our health

5. July 2025

Microplastic removal: SPIONs and magnetization

8. July 2025The Illusion of Solutions: When "Microplastic Removal" Becomes Displacement

Wastewater treatment plants worldwide are often praised as the solution to the microplastics problem. Modern filtration technologies and cyclone separators achieve impressive removal rates of up to 99% of microplastic particles from wastewater according to their own claims. We also frequently read about so-called SPIONs. These figures create the impression of successful problem-solving – but the reality is more complex and problematic than it appears.

Our new blog article argues scientifically that a genuine solution must address the source instead of merely shifting the problem. The "out of sight, out of mind" mentality of traditional filtration and cyclone technologies leads to an invisible but growing environmental burden from microplastics.

The Fate Paradox: Where Do the Microplastics Really Go?

The touted high removal rates for microplastics within the treatment stages of wastewater treatment plants do not mean that microplastic particles are actually destroyed. Wastewater treatment plants are considered major sources of microplastic contamination in aquatic environments, even though they are paradoxically marketed as solutions.

Facts on microplastic concentrations:

- Inflow: repeatedly 30,000 – 100,000 particles per liter, rarely less

- Outflow: repeatedly around 100, rarely less than 10, sometimes up to 1,000 particles per liter, depending on treatment stage, design, and process technology

- Sewage sludge: scientifically published between 4,400 to 240,000 particles per kilogram, reproducibility and recovery rates are missing

Sewage Sludge as a Microplastic Reservoir

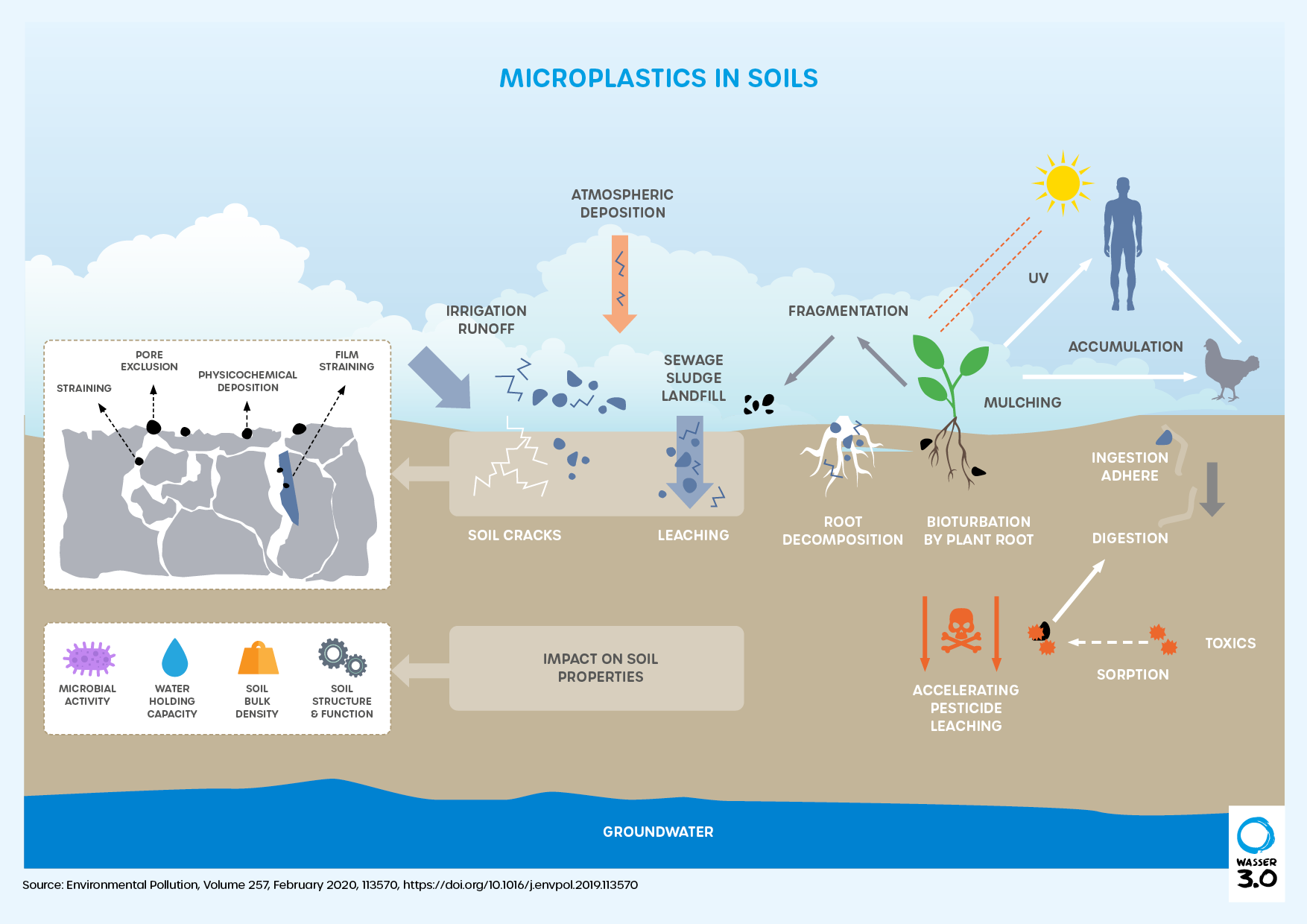

Approximately 60-99% of microplastic particles in wastewater treatment plant inflows are ultimately transferred to the sewage sludge, where concentrations of 1,000 to 186,700 MPs/kg dry weight accumulate. This concentrated enrichment leads to a fundamental problem: the microplastic doesn't disappear but is merely shifted to another environmental matrix, for example into soils.

Microplastics in Soil © Wasser 3.0

Filtration Technology: Highly Efficient but Incomplete

Modern membrane technologies such as microfiltration, ultrafiltration, and reverse osmosis are considered the most effective methods for microplastic separation. Membrane technologies are the most effective and promising technologies for microplastic removal from water and wastewater. Nevertheless, significant problems exist:

- Membrane fouling by microplastics: Microplastic particles have irregular shapes that can wear down filters and pose a high risk for membrane fouling due to their surface properties.

- Secondary contamination: Research suggests that plastic membranes used in reverse osmosis may themselves add microplastics to the water.

- Physical Limits of Particle Size: Cyclone separators use centrifugal forces for particle separation and can achieve remarkable results under special conditions. The critical limitation of hydrocyclone/cyclone separators lies in their low collection efficiency for fine particles, which is undesirable for comprehensive microplastic removal (particle mixtures) as well as for most industrial applications.

The Environmental Displacement Dilemma: From Water to Soil: Agricultural Contamination

The supposed "solution" through filtration and cyclones leads to a systemic environmental problem. Treatment plants essentially take microplastic particles out of wastewater and concentrate them in sludge. This sludge is frequently used as agricultural fertilizer.

This results in the quantitative dimension of the problem: with improper management, more than 800 billion microplastic and plastic particles per year can be spread via sewage sludge. Additionally, two underestimated long-term factors come into play: long-term accumulation in soils and minimal natural mobilization.

Minimal natural mobilization means that surface water runoff has only a negligible influence on the discharge of microplastics from agricultural soils. Instead, there is almost permanent enrichment in terrestrial ecosystems.

Unintended Problem Intensification in Wastewater Treatment Plants Previously Overlooked

Latest research suggests that wastewater treatment plants may circulate some larger microplastic particles repeatedly through the treatment process, breaking them down until they are small enough to escape in the wastewater.

This results in continuous release despite touted high efficiency. Even with 90% removal efficiency, this means: the amount of anthropogenic plastic waste in the range of 25 μm - 50 mm still released with wastewater amounted to around 300 million microplastic particles per day.

What Helps Real Solutions Forward? First: New, Fast Microplastic Analytics

While conventional detection methods like FT-IR and Raman spectroscopy are complicated, time-consuming, and expensive, we have developed revolutionary detection technology based on innovative fluorescence markers that enables fast, cost-effective, and scientifically validated microplastic analytics.

Functional principle of fluorescence markers: The innovative fluorescence dyes (MP-1) are added to the water sample and selectively stain microplastic particles (strong fluorescence), but not natural particles (no or only negligible fluorescence signal). The marker MP-1 was developed through years of research to selectively stain microplastics.

Practical Advantages Over Conventional Methods

The standardized sampling procedure and directly connected microplastic analysis requires less than 45 minutes of work time per sample, while conventional methods deliver results in up to four weeks. The technology has already been tested and validated in over 700 samples in municipal treatment plant effluent and over 500 sampling points in water monitoring.

The great advantage of our method lies in automated imaging. This is far faster and more reliable than manual counting under a fluorescence microscope, minimizing human error sources.

And Second: Genuine Microplastic Removal with Clump & Skim

In contrast to conventional filtration and cyclone technologies, we have developed a fundamentally different approach with our Wasser 3.0 PE-X® technology. The process is based on the principle of agglomeration-fixation (Clump & Skim), where all microplastic particles are clumped into particle compounds – independent of polymer type or water type.

Functionality of the Clump & Skim Process: Completely health-safe hybrid silica gels are added to the contaminated water. Through stirring, the hybrid silica gels clump with the microplastics into popcorn-like agglomerates that float to the water surface and are separated filter-free with a skimmer.

Genuine Removal Instead of Concentration: The Wasser 3.0 PE-X® technology led to an average reduction of micropollutants by 86 ± 2% in municipal wastewater treatment plant environments, depending on the overall system design. Removal rates for microplastics are reproducibly over 95%.

The advantage over all other processes:

- Coarse-pore separation units are used for the formed agglomerates, saving both costs and immense maintenance effort

- The system requires 20% lower capital costs and up to 75% lower operating costs compared to traditional membrane filtration or hydro-cyclone systems

The World First: Circular Economy Reuse

The decisive difference to conventional technologies lies in reuse: the so-called agglomerates can be reused after removal from water. Currently, building materials, for example in cement production, are coming into focus.

With our technology, 100% of waste removed can be reused, increasing the contribution to resource conservation while simultaneously creating a new secondary income source through the value chain.

Maximum Efficiency and Variability: Systemic Integration Instead of Retrofitting

The low-tech plants and filter-free processes can be cost-effectively implemented not only in central wastewater treatment plants but especially within the plastic value chain as a preventive measure. The modularity, scalability, and high adaptability of technology enable problem-free combination as an addition to existing treatment methods.

Breaking Away from Traditional Thinking: The Necessity of a Paradigm Shift

Current filtration and cyclone technologies do not solve the microplastics problem – they merely shift it from one environmental matrix to another. The seemingly high removal rates from wastewater mask the actual problem displacement into terrestrial ecosystems, where microplastics accumulate long-term.

With many touted microplastic removal technologies, one finds:

- Concentration instead of elimination: Microplastics are not destroyed but only redistributed

- Systemic displacement: From aquatic to terrestrial ecosystems

- Long-term accumulation: Minimal natural degradation processes lead to permanent environmental burden

A real solution approach must address the source: reduction of microplastic input, development of biodegradable alternatives, and technologies for actual decomposition or transformation of microplastic particles. The current "out of sight, out of mind" mentality leads to an invisible but growing environmental catastrophe that will confront future generations with exponentially larger problems. With us, you get answers and real solutions for more water without microplastics.