Microplastic Removal from Water and Wastewater – Innovative Clump & Skim Technology

Remove microplastics efficiently and cost-effectively from (waste)waters with the filterless Wasser 3.0 PE-X® technology. Our innovative Agglomeration-Fixation (Clump & Skim) reduces microplastics, micropollutants, and COD with minimal energy and maintenance effort – the ecological alternative to conventional filtration processes.

Why is Microplastic Removal from Wastewater Crucial?

Microplastics represent one of the biggest ecological challenges of our time. Millions of tons of plastic particles enter waters, soil, and ultimately the food chain every year. Two sources are particularly critical:

- Municipal Wastewater Treatment Plants: Despite multi-stage treatment, microplastic particles still enter rivers and seas daily via the effluent.

- Industrial Production Processes: The manufacturing, processing, and use of plastics generate microplastic emissions that have previously been largely uncontrolled.

With the Wasser 3.0 PE-X® technology, we offer a scalable, cost-efficient solution for microplastic reduction – both for downstream treatment and as a preventive measure in production.

Microplastic removal using Clump & Skim Technology

With Wasser 3.0 PE-X® we have developed the first filter-free process solution for the fast, efficient, and cost-effective removal of microplastics and other pollutant classes from different types of water.

Based on the principle of agglomeration-fixation (in short: clump & skim) and by precisely matching materials and technology to the process in question, all microplastic particles are clumped together to form particle aggregates - regardless of polymer or water type.

Coarse-pored separation units are used to remove the formed agglomerates. This saves both costs and immense maintenance effort, which increases continuously with decreasing particle size.

Upon customer request, tailor-made solutions are developed, adapted to the composition of the wastewater and the (legal) requirements for discharge into the wastewater system.

The goal is to reduce the overall pollutant load in the wastewater, especially microplastics, micropollutants and COD, and to improve the overall sustainability of the processes without incurring high energy requirements, costs, and maintenance efforts.

What is Wasser 3.0 PE-X® Technology?

Wasser 3.0 PE-X® is the first filter-free process solution for the fast, efficient, and economical removal of microplastics and other pollutant classes from various water types. The technology is based on the principle of Agglomeration-Fixation, also known as Clump & Skim.

How Does Clump & Skim Work?

- Agglomeration: Microplastic particles are clumped into larger particle aggregates through precisely matched material-technology compositions – regardless of polymer type, particle size, or water type.

- Separation: The formed agglomerates are separated using coarse-pored separation units. This saves immense costs and maintenance effort compared to fine filtration processes.

- Removal: The microplastic agglomerates are removed from the process, while cleaned water can be returned to the cycle or safely discharged.

Advantages of Filterless Microplastic Removal

Compared to filtration processes, which are intensive in terms of installation, maintenance, energy, and resources, Wasser 3.0 remove offers decisive advantages:

- Low Investment and Operating Costs: Minimal energy demand and reduced maintenance due to the filter-free process.

- High Efficiency with Low Effort: Coarse-pored separation units instead of expensive micro- or ultra-filtration membranes.

- Modular and Adaptive Solution: Flexibly adaptable to different contamination scenarios and water types.

- Scalable: From the laboratory and pilot plant to industrial full-stream operation.

- Multifunctional: Reduces not only microplastics but also micropollutants and COD (Chemical Oxygen Demand).

Application Areas of Microplastic Removal

Municipal Wastewater Treatment Plants and Wastewater Purification

Our low-tech systems can be cost-effectively integrated into central wastewater treatment plants to significantly reduce microplastic concentrations in the effluent. The new EU Urban Wastewater Treatment Directive (91/271/EEC) requires wastewater treatment plants to conduct regular microplastic measurements – our technology offers the suitable solution.

→ Learn more about our complete solutions for wastewater treatment plants

Industrial Processes and Microplastic-Free Production

Particularly in the plastic value chain, the Wasser 3.0 PE-X® technology can be used as a preventative measure to prevent the transfer of plastics from production processes into the environment. From granulate manufacturers to processors and the recycling industry – our modular systems adapt to your processes.

→ Discover our solutions for industry and production

- Plastic processing and production

- Textile industry (fiber breakage, microfibers)

- Recycling facilities

- Tire abrasion hotspots (car washes, road drainage)

- Paint shops and surface treatment

Microplastic Analytics: Measure and Monitor

Before you can remove microplastics, you need to know how much is present. Our fluorescence-based microplastic analysis enables fast, cost-effective, and scientifically validated monitoring of your water and wastewater samples.

With our complete service, we handle the standardized on-site sampling, laboratory detection, and comprehensive reporting – everything from a single source.

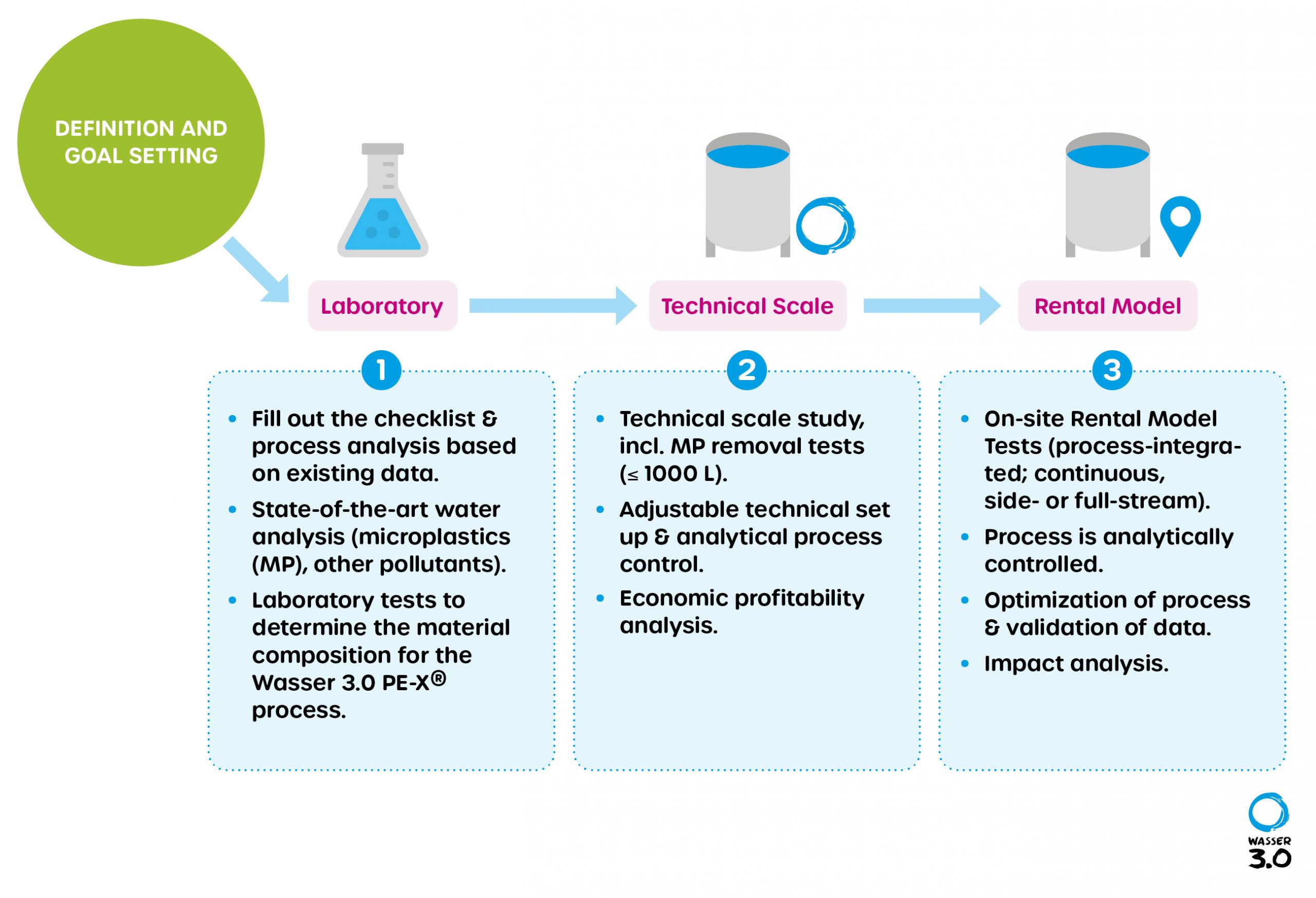

Modular Plant Construction and Rental Model

Our systems are modularly constructed and can be provided as a rental model for long-term trials or as a permanent installation:

- Container-based Plug-and-Play solutions

- Batch or continuous operation

- Adaptable dosage and contact time – individually tailored to your process

- Integration into existing infrastructure as an add-on or standalone solution

- Scaling from pilot plant to industrial full-scale operation

Sustainability and UN Sustainable Development Goals

By using the Wasser 3.0 PE-X® technology, you measurably contribute to achieving several UN Sustainable Development Goals:

- SDG 6 – Clean Water: Reduction of microplastics in waters

- SDG 12 – Sustainable Production: Circular economy and resource conservation

- SDG 14 – Life Below Water: Protection of marine ecosystems

- CO₂ and Energy Savings: Through a low-tech approach and minimal maintenance effort

Implement Microplastic Removal Now

Do you want to remove microplastics from your processes or your wastewater? We are happy to advise you on customized solutions – from the initial feasibility study to complete system integration.

Contact us for:

- Free initial consultation and process analysis

- Feasibility studies and preliminary trials in our pilot plant

- Rental model for long-term trials (>1 month)

- Complete service for microplastic analytics